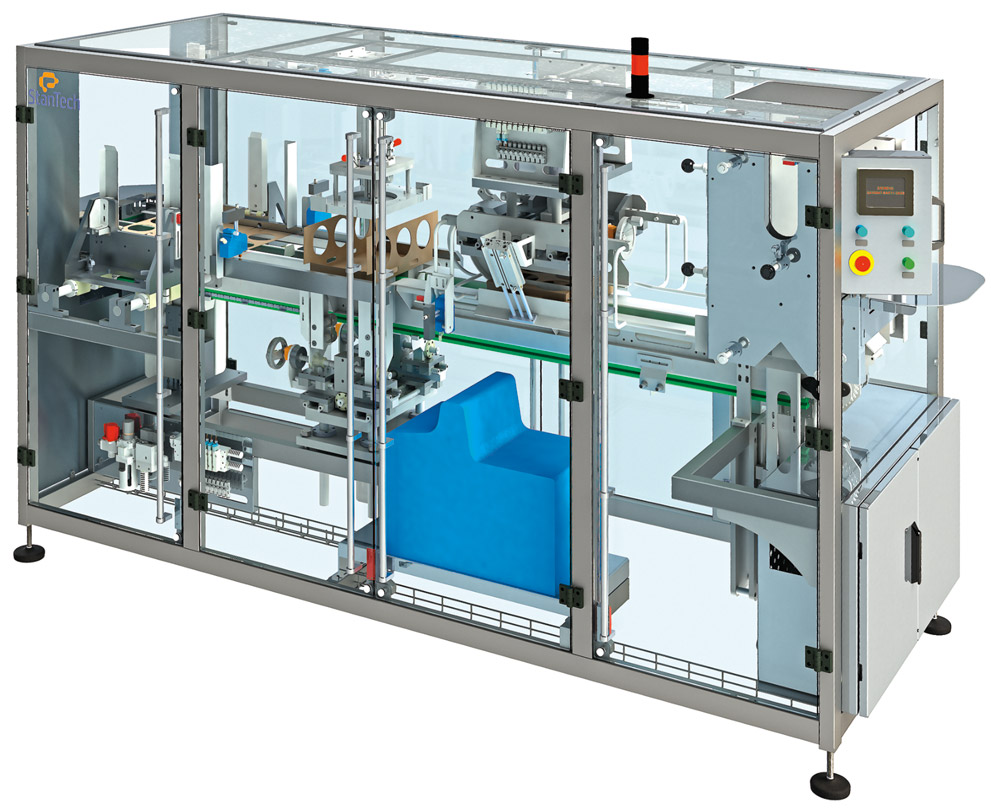

SPIDER

Tray former capable of creating various tray designs, including open trays, hinged lids, and fold-over tops.

Tray FormerSpider

Spider, a versatile tray former designed to meet the diverse needs of the packaging industry. The Spider offers a range of tray packer solutions, ensuring flexibility and efficiency in food industry.

Key Features

- Tray Solutions

Capable of forming open trays, closed trays with cutouts to hold products, closed trays with supporting sealed columns in the middle, and trays with hinged lids.

- Stand-Alone or Integrated Operation

Can operate as a stand-alone machine or be integrated into a production line with an optional pick-and-place module for cups loading.

- Adjustable Dimensions

Easily adjustable to accommodate different tray dimensions.

- High Capacity

Capable of processing up to 30 trays per minute.

Technical Specifications

| SPEED | 30 trays per minute |

| BOX TYPE | Flat blank |

| AIR PRESSURE | 6 bar / 90 PSI |

| BOX SEALING | HOT MELT, TUCK-IN (OPTIONAL) |

| DRIVES | Servo Motors |

| CONTROLS | ALLEN BRADLEY |

| SYSTEM MONITORING | HMI |

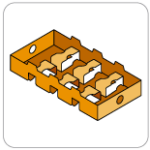

Tray Options

Product Application

Product that can be packed in trays

CANS – CUPS

Innovative Design

- Robust Construction: Built for durability and long-term performance.

- User-Friendly Interface: HMI operator panel for easy monitoring and control.

- Flexible Operation: Suitable for a wide range of product types and packaging configurations.

REFERENCES

Advanced Features

- Precise Tray Formation: Ensures accurate and consistent tray formation

- Efficient Sealing: Hot melt system for secure and reliable tray sealing

- Integration Capability: Optional pick-and-place module for seamless integration into production lines